ETP Feeds With BactaServe for COD/ BOD Removal from Pharma Industry’s Wastewater

1. Background:-

With a presence in 138 countries on six continents, pharma company is now the world’s largest integrated supplier of solid dosage products and services – providing hard-shell capsules, film and foil barrier solutions. Founded in Mumbai, India in 1961,now serves pharmaceutical companies all over the world, touching almost every aspect of solid dosage manufacturing.

2. Challenges in ETP operation & problems:

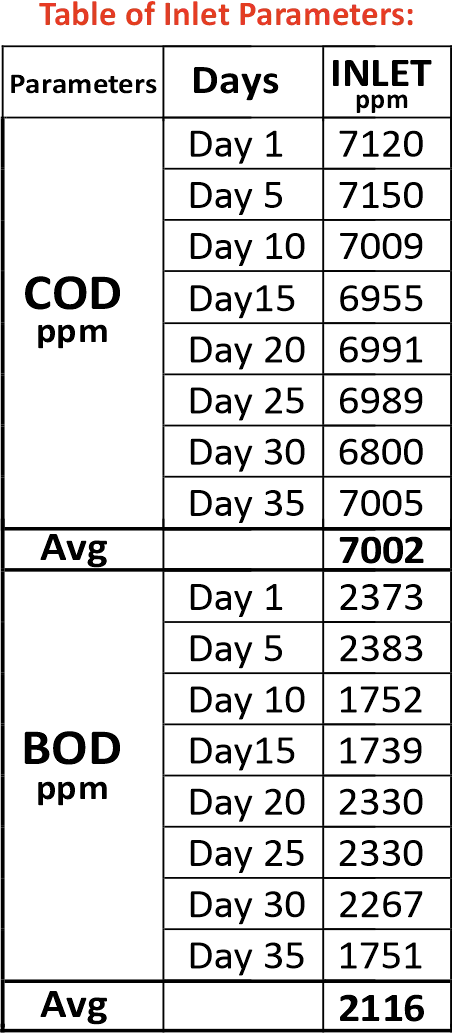

COD and BOD were very high in the efluent

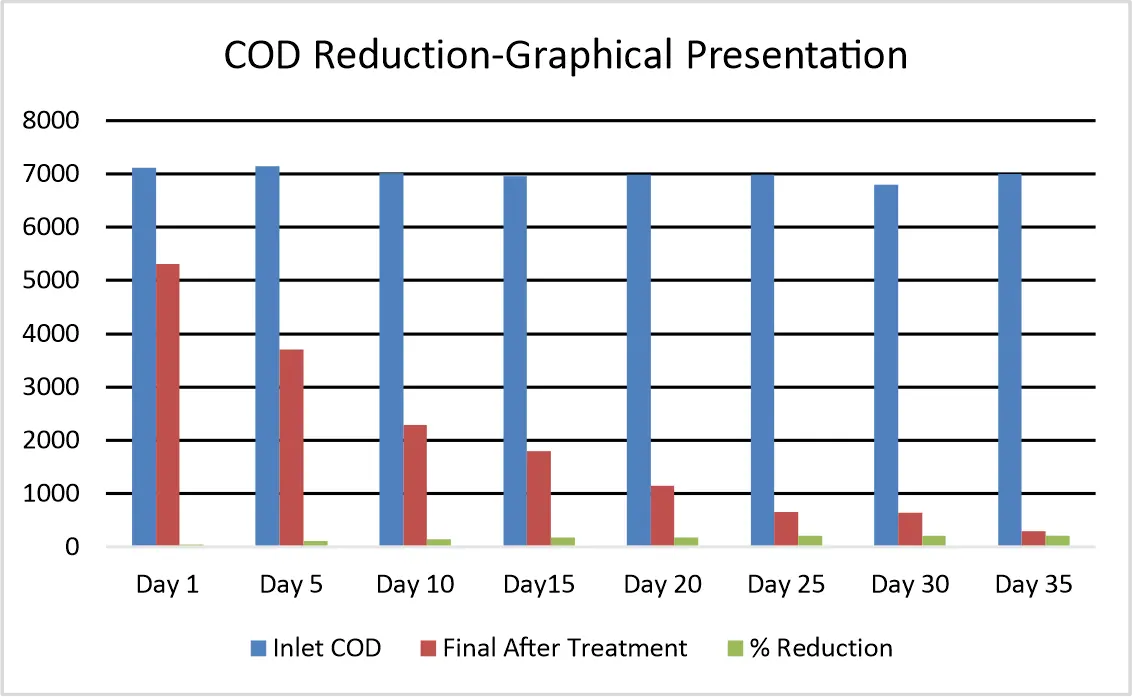

COD 7000 ppm, BOD is 2000 ppm and it was in the same higher range through out.

A high level of BOD can reduce dissolved oxygen (DO), thereby harming the local environment if the efluent is discharged

Water with high COD/BOD often has poor aesthetic qualities, such as bad odour, murky appearance, and an unpleasant taste

3. Special Technical Solution:

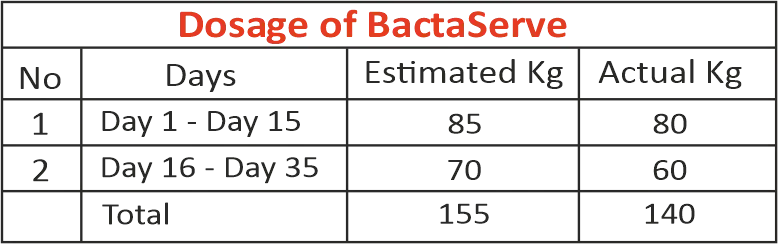

Initial feed of BOD/COD was extremely high. We have suggested a solution -BactaServe Anaerobic and Pharma bioculture.

BactaServe is specially formulated naturally occurring, nonpathogenic, Non genetically altered blend of bacteria which can grow over wide temperature range 5-45°C. BactaServe when added in waste water treatment systems, bacteria starts multiplying immediately to create higher Biomass content. This helps in bio-degradation of BOD content of the waste water.

3.1 Special features to highlight:

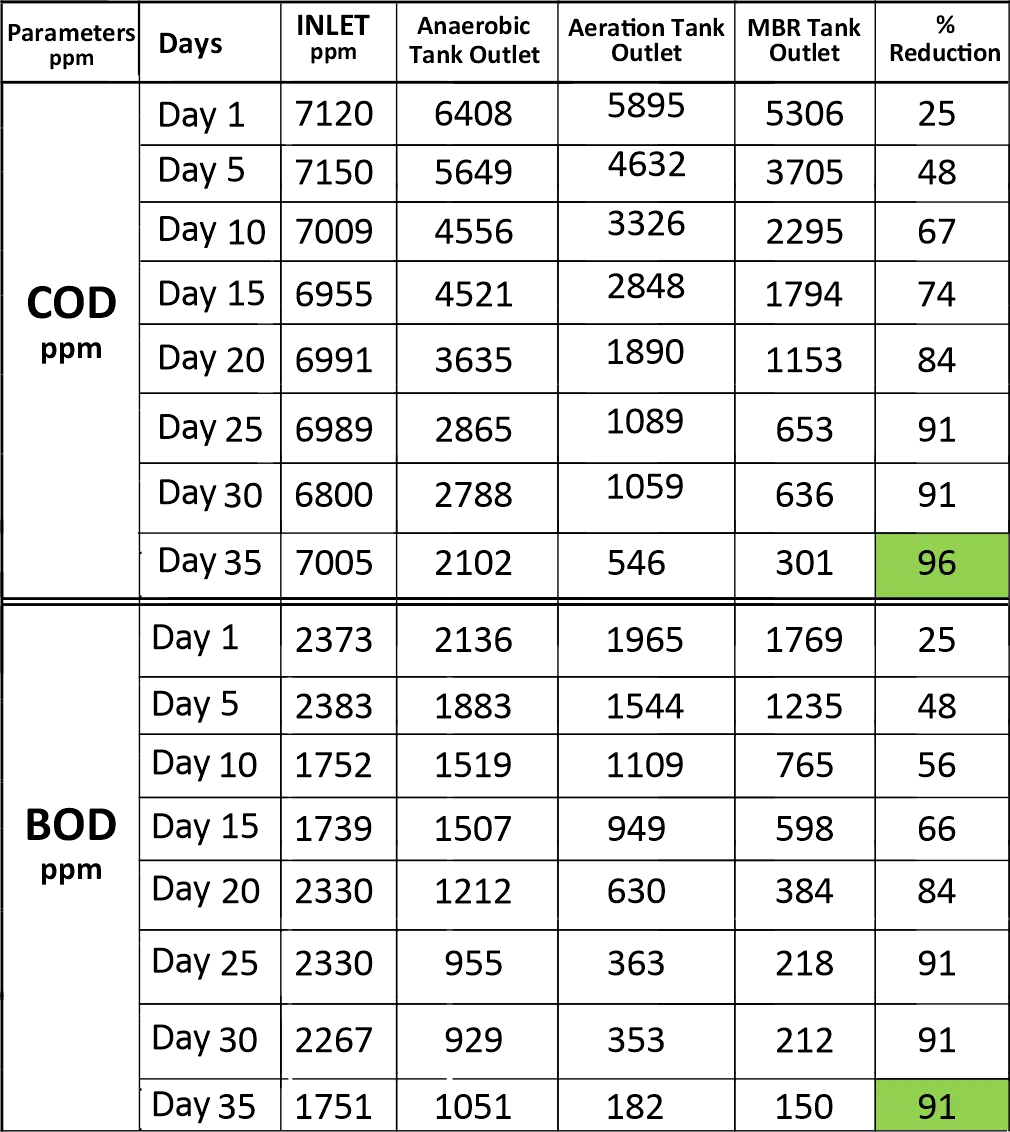

COD of day 1 at Anaerobic tank outlet was 6408 ppm, at Aeration tank outlet 5895, in MBR tank outlet 5306 ppm

Day 10, Anaerobic tank outlet COD was 4556 ppm, Aeration tank outlet 3326, MBR tank outlet 2295 ppm

After 15th days BactaServe dosage 48% reduction achieved in Anaerobic tank for COD

After a month, 82% reduction found in MBR tank outlet COD

Total 96% COD reduction achieved

Sufficient growth of MLSS found in 20 days

Maintaining flow 2 m3/hr, after 10 days of MLSS development

Increased flow from 3.5 m3/day to 4.5 m3/day, during this DO – 4 ppm, pH – 6.5 to 7.5

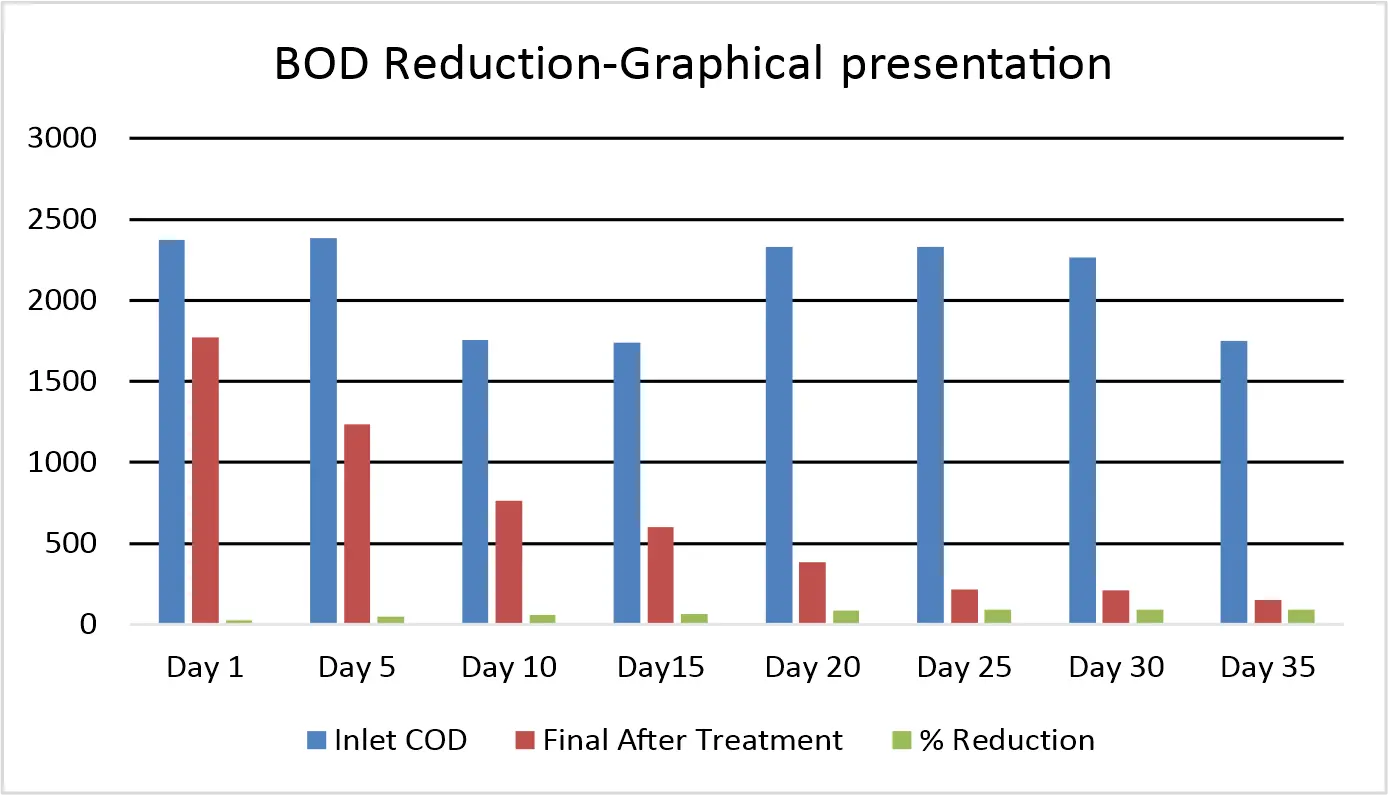

BOD of inlet Day 1 was 2373 ppm, Anaerobic tank outlet 2136, MBR tank outlet was 1769 ppm , BOD of Day 15 - MBR Tank outlet was 598 ppm

91% reduction in BOD value achieved

4. Executive Summary:

This project of pharma ETP was challenging due to high COD/BOD.

Average MLSS earlier was 2000 ppm and after Bactaserve 4000 ppm

Earlier average MLVSS– 1400 ppm and after Bactaserve bioculture dosing its 2800 ppm.

This time increased flow by 20% of 170 m3/day.

Bactaserve slurry preparation and dosing has clearly shown, a spike in MLSS

5. Achievements:

Bactaserve bioculture solved this issue with bacterial strains

COD day 1 inlet was 7120 ppm and after Bactaserve pharma dosing, at day 35 outlet was 301 ppm

BOD at day 1 inlet was 2373 ppm & at day 35, outlet was 150 ppm

We are happy to highlight 91% reduction in BODand 96% reduction in COD - We have successfully solved the problem of ETP

.jpg)